The Real Cost of OSHA Fines: Insights from CertifyMe’s Survey

Safety is a crucial element in the daily operations of companies using forklifts and similar powered industrial vehicles. The U.S. Occupational Safety & Health Administration (OSHA) places utmost importance on this aspect, emphasizing that safety is the key component in forklift operations.

OSHA continually highlights the necessity of safe forklift operation, but there’s always room for further insights. This is where a recent forklift survey by CertifyMe comes in, providing a detailed analysis and broader understanding of the safety practices in this field.

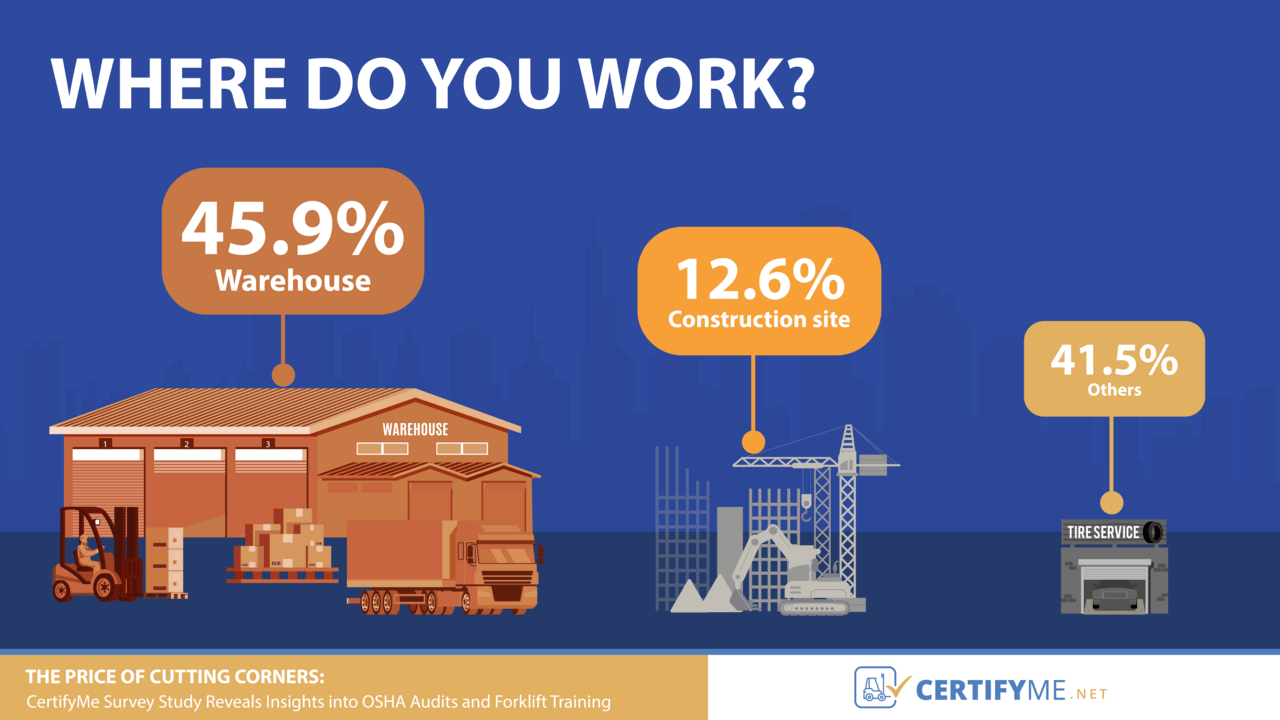

The extensive survey, which involved over 100 customers from a range of industries and sectors, garnered responses from 111 CertifyMe clients. Almost half of these respondents, 46%, work in the warehousing sector, underscoring the significant role of forklifts in this industry. Approximately 13% of the participants come from the construction sector. The rest, accounting for 41%, hail from diverse fields including office environments, marinas, manufacturing facilities, airport hangars, retail outlets like tire stores, recycling firms, and many others, demonstrating the widespread use of forklifts in various professional settings.

Here’s a breakdown of the forklift survey participants by industry:

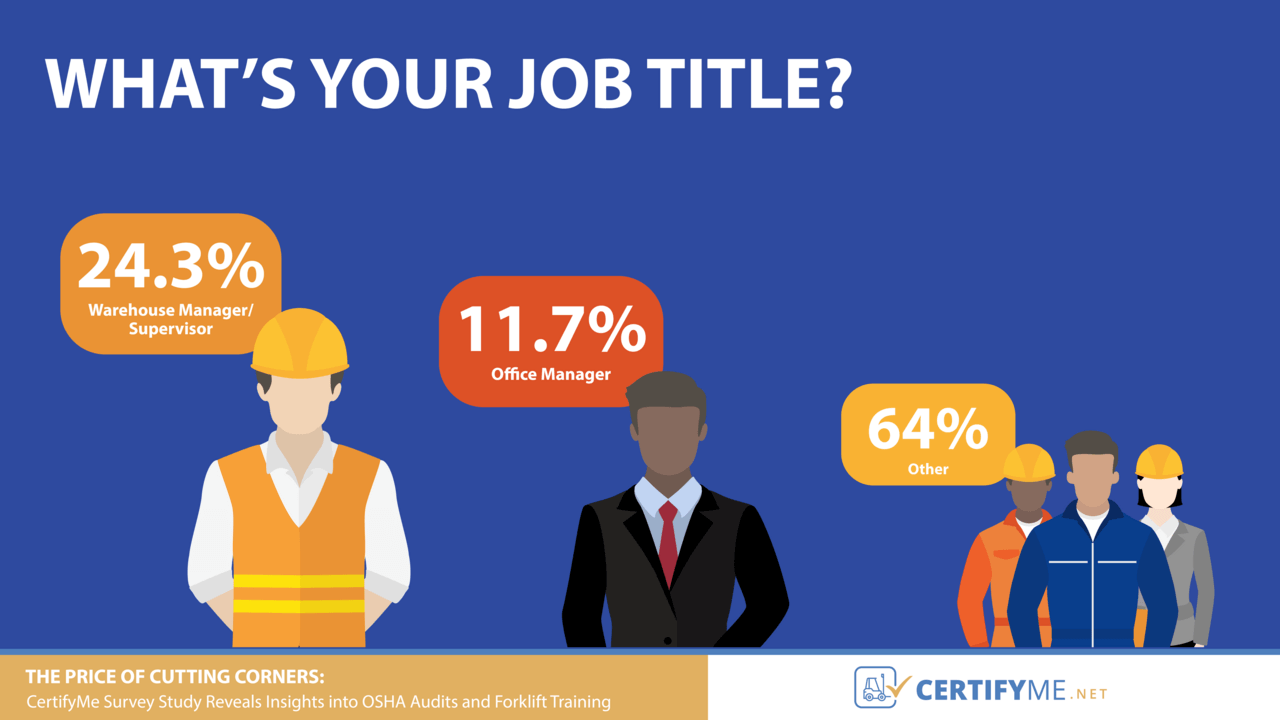

Role-wise, the most common job title is warehouse manager/supervisor, followed by office manager. This role is commonly involved in safety policies and procedures, compliance checks, training, and more.

OSHA Audits: More Common than You Think

Forklift accidents, injuries, and near-misses can lead to the much-dreaded OSHA audit or inspection. Many companies mistakenly believe they will never be audited, but the CertifyMe survey sheds light on the reality.

Contrary to what some safety supervisors might think, all companies are potentially subject to OSHA’s scrutiny, particularly following a forklift-related incident.

Neglecting safety measures is a risky practice. If a company’s safety protocols are outdated or not in compliance with OSHA standards, the likelihood of incidents increases, attracting OSHA’s attention.

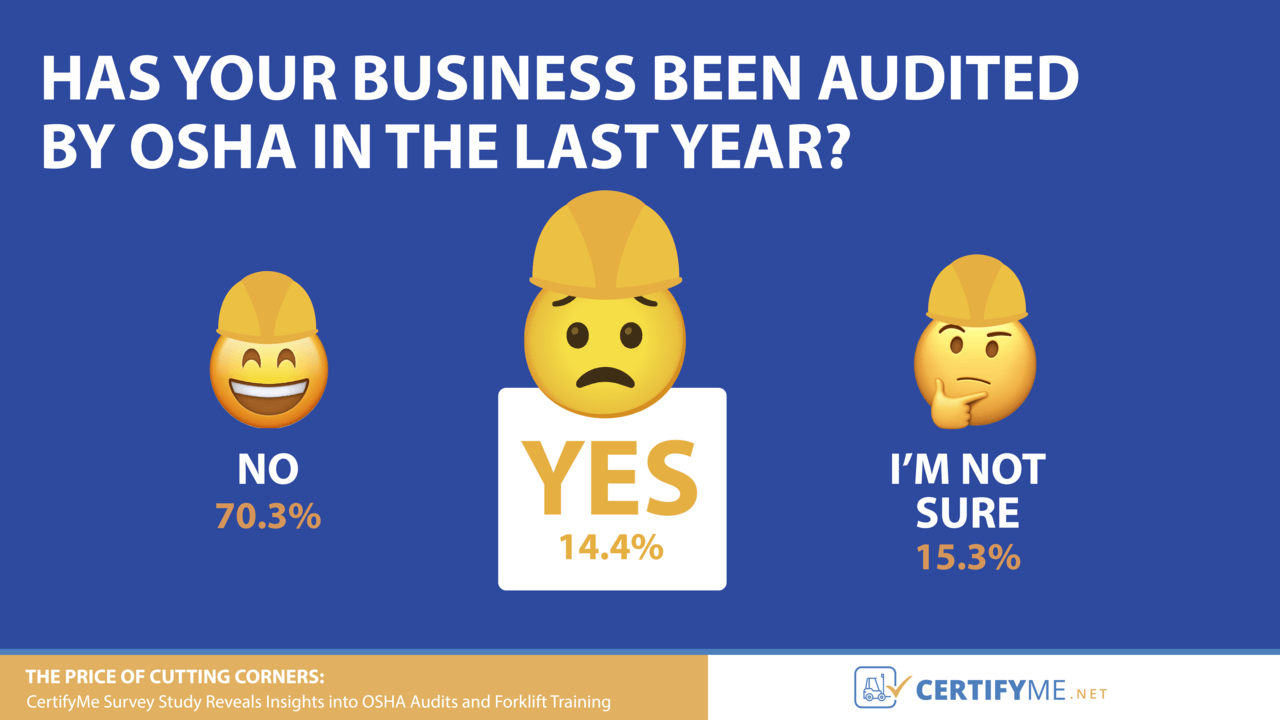

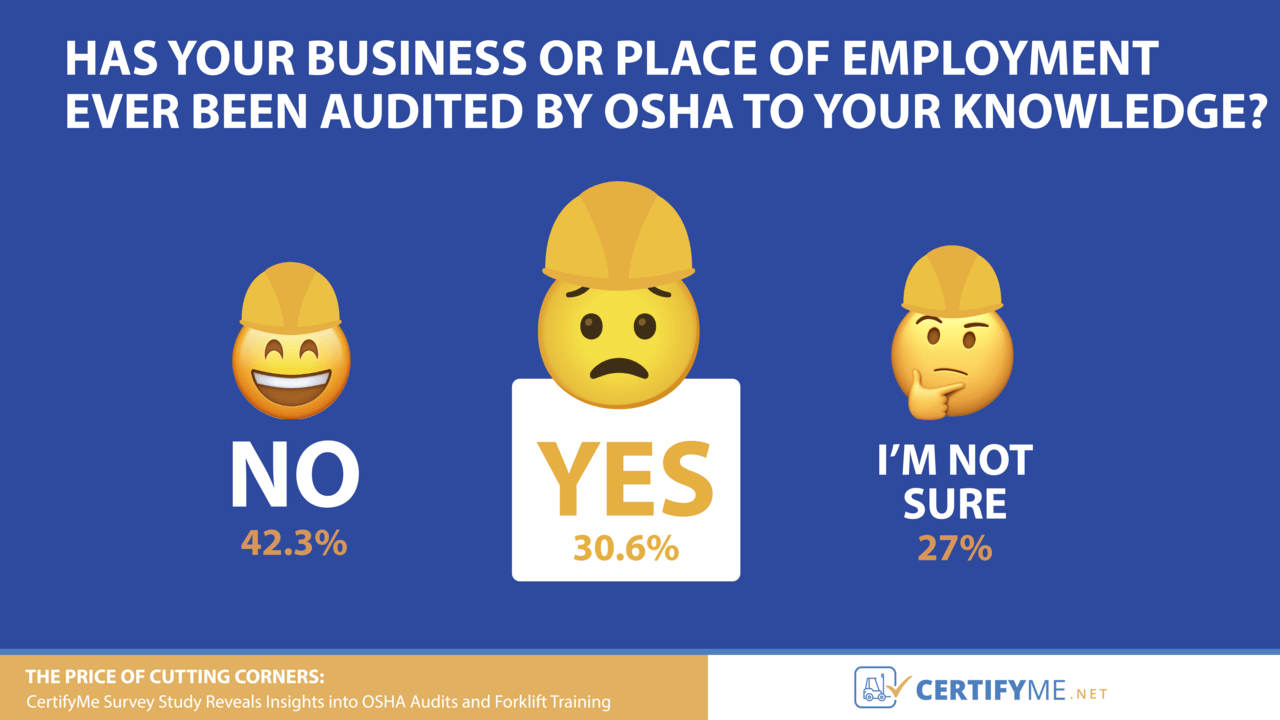

The survey by CertifyMe found that about one-third (30.6%) of companies reported having undergone an OSHA audit, with 14% of these audits occurring in the last year. Interestingly, 27% of respondents were uncertain if their workplace had been audited, suggesting a lack of awareness, as OSHA audits typically involve significant documentation, interviews, and impact on the workplace.

While companies confidently reporting an OSHA audit do not represent the majority of the survey participants, this does not rule out the possibility of audits for other companies. It’s important to note that OSHA doesn’t need an injury or accident to initiate an inspection; they can audit any company at any time according to their guidelines.

Here’s a breakdown of our OSHA inspection inquiry:

OSHA Fines: Amounts, Consequences & More

Effective January 15, 2023, OSHA enacted increased penalties for safety violations. There are three main categories of penalties, and here’s the cost overview:

- Serious (and Other Than Serious Posting Requirements): $15,625 per violation

- Failure to Abate: $15,625 per day beyond the abatement date

- Willful or Repeated: $156,259 per violation

When it comes to OSHA penalties, there are two important aspects to consider. Firstly, a single incident with a forklift can lead to multiple fines. Imagine a scenario where a forklift accident occurs due to an uncertified driver and inadequate lighting in the warehouse. This situation could result in OSHA fines exceeding $170,000, especially if the lack of proper training is a recurring issue and the poor lighting is deemed a serious violation. Secondly, ensuring that forklift operators have up-to-date certification can significantly lower the risk of incurring hefty OSHA fines. Adequate training and adherence to OSHA’s current standards can lessen the likelihood of accidents and help avoid costly penalties for “willful or repeated” violations.

Another critical consideration in terms of staying compliant and not cutting corners with safety has to do with the types of violations OSHA looks for. Every year, the agency announces the 10 most frequently cited violations, which often result in expensive fines. Many of these violations happen in industries using forklifts, including warehousing, construction, etc.

The True Cost of Ignoring Safety & Compliance: Accidents and Injuries

Financial implications are significant, but the safety of employees is even more crucial and paramount. While monetary fines can severely impact a company’s finances, a serious forklift accident can cause debilitating injuries to an employee.

Research consistently demonstrates that proper training and awareness of safety measures – the primary aims of any effective training program – are key in preventing accidents. Therefore, the most effective strategy to avoid OSHA fines and penalties is not just hoping to evade audits or overlooking essential safety measures. Instead, it involves implementing a sustainable, logically sound, and effective training regime within the company’s operations.

Consider this perspective: investing in comprehensive OSHA-compliant training for your employees at the outset is beneficial in the long run, as it significantly reduces the likelihood of facing OSHA penalties.

Concerning the frequency of forklift accidents, here’s a striking fact: annually, at least 35,000 injuries are caused by forklift incidents. These injuries affect not just the drivers but also pedestrians.

OSHA’s research further indicates that these accidents lead to nearly 10,000 workers missing work each year. When factoring in additional expenses like rehabilitation and physical therapy, the importance of having current forklift training and certification becomes evident.

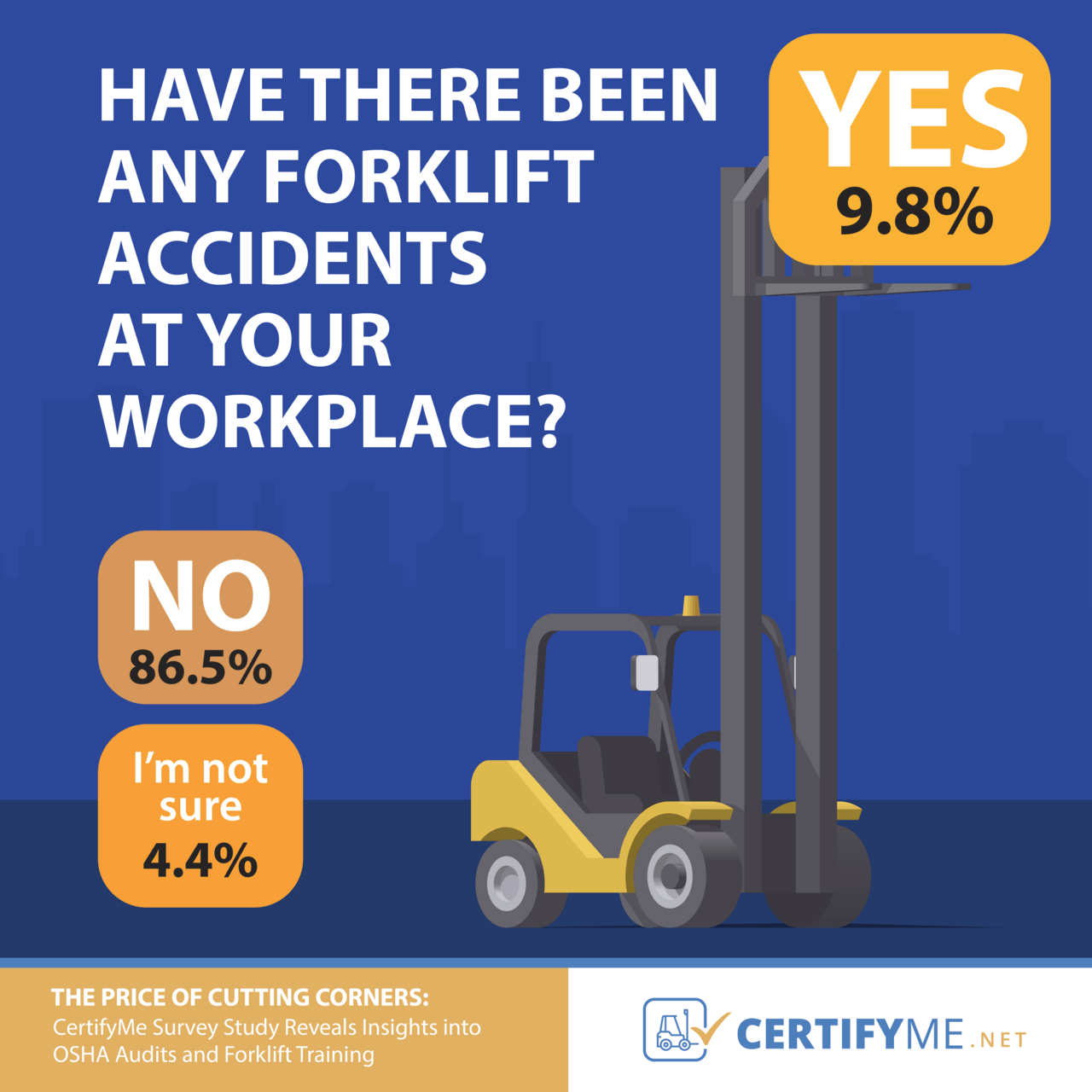

A notable point from our survey is that less than 6% of participants (all trained and certified through CertifyMe.net) reported experiencing a forklift accident at their workplace. This percentage is significantly lower than the overall accident rate observed and reported by OSHA.

Forklift Training & Certification: There’s No Excuse to Skip on Safety

With proper OSHA certification, your forklift operators not only perform safer on the job – they’re more productive and confident, too! Remember, all employers are required by law (OSHA guideline 1926.21) to provide training and certification for their workers. That’s why having a training partner like CertifyMe.net helps you keep track of all the rules and regulations; our training is specifically designed to provide practical, safety-first driving guidelines.

With proper OSHA certification, your forklift operators not only perform safer on the job – they’re more productive and confident, too! Remember, all employers are required by law (OSHA guideline 1926.21) to provide training and certification for their workers. That’s why having a training partner like CertifyMe.net helps you keep track of all the rules and regulations; our training is specifically designed to provide practical, safety-first driving guidelines.

Some of these regulations include the following:

- Always wear seatbelts while driving a forklift.

- Be cautious of clearance distances.

- Stay alert for nearby pedestrians in the vicinity of forklift traffic.

- Use a spotter for any blind spots or areas where pedestrians are present.

- Keep a safe distance when driving around ramps, loading docks, and platform edges.

- Always know the maximum load requirements for your forklifts.

- And many more.

There are two main ways to get OSHA-compliant certification for forklift operation. The first is through an online training platform, such as CertifyMe.net. In this approach, all the course material is accessed and completed online. Employers set up login details for their company and each employee needing the training. After finishing the online component, there’s a hands-on skills evaluation at the workplace to confirm that the trainees can safely operate a forklift.

The second option is a kit-based training program available from ForkliftCertification.com, which is associated with CertifyMe. This method provides training materials, including checklists and safety guidelines, on a USB flash drive. Similar to the online method, trainees must pass an in-person skills test to receive their certification.

Both training methods are cost-effective for businesses, eliminating the need and expense of sending employees to external training locations.

The Training Bottom Line: Training is For Everyone – Including You!

Our survey data clearly shows that keeping your forklift certification current is a wise decision. Neglecting safety measures is not worth the risk, especially with the possibility of OSHA inspections. By implementing a robust safety program, you can reduce your company’s risk exposure. CertifyMe is available to assist you in reaching your safety objectives.

To protect your employees and business with OSHA-recognized certification, register with CertifyMe today!

Follow step-by-step instructions to get OSHA compliant!

This low-cost program can be completed anytime, anywhere!